Standards

ICRA maintains rigorous quality and performance standards in compressor remanufacturing. We comply with international regulations, use advanced technologies, and implement strict testing protocols to ensure durability, efficiency, and environmental responsibility.

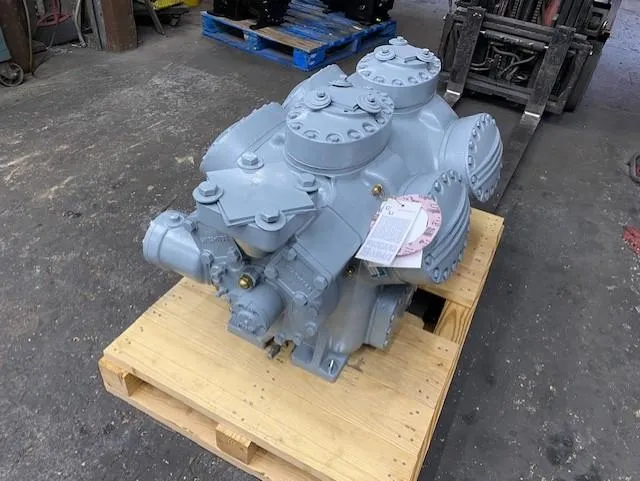

ICRA Standards for Remanufacturing Semi-Hermetic Compressors

The Standards put forth for the remanufacture of refrigeration compressors are to be considered a minimal standard to meet the basic intent of ICRA to ascertain that its members have guidance in producing quality, trouble free products. No standards can cover all possible procedures, materials , tolerances, techniques and testing that can be applied to such individual or company attitudes, training and facilities. This is evident when one considers other fields of maintenance, such as the automotive field, electrical and mechanical service centers, which vary greatly in their competency and the products the produce.

ICRA was formed by concerned compressor remanufactures to see that this particular trade retain a professional air such that the general public may feel confident in dealing with any of it’s many members. To this end, ICRA encourages potential users of the services of it’s members to investigate them, by examination of their facilities, by talking to other users or by whatever means appear practical to make a comparison of the service facilities or methods.

RECEIVING & DISASSEMBLING

Upon receipt of a compressor the nameplate data and the accessory devices attached should be recorded. As the unit is being disassembled, condition of the parts should be noted such that the cause of failure can be determined. The oil should be drained into a container to ascertain the amount and condition of the oil.

CLEANING

After the unit is totally disassembled all parts should be cleaned and protected from rusting. Various methods may be used to accomplish the cleaning; alkali and acid baths bead blasting, hot high pressure washing, etc. Whatever method is used the unit must be thoroughly washed afterward to be certain no cleaning chemical remains on (or entrapped in) the unit body or parts.

CLEANING

After the unit is totally disassembled all parts should be cleaned and protected from rusting. Various methods may be used to accomplish the cleaning; alkali and acid baths bead blasting, hot high pressure washing, etc. Whatever method is used the unit must be thoroughly washed afterward to be certain no cleaning chemical remains on (or entrapped in) the unit body or parts.

PARTS INSPECTION

Each part should be thoroughly inspected visually and with instruments as required to determine that they are within industry tolerances and free from defects. The Body itself should be inspected for scored cylinder walls, bore size, clear passages and for cracks. Pistons should be checked for proper tolerance, worn ring grooves and worn pin fit. Connecting Rods should be checked for pin fit, crankshaft fit and straightness. The crankshaft should have all surfaces and fits checked. Oil pumps should be tested in both directions with a bench tester or on the unit itself when reassembled. Bearings should be checked for size and alignment in the unit. The motor stator should be visually inspected after cleaning, given a megger check, high-pot test, surge comparator check and core test. The rotor may be given an open rotor bar test on a growler or by other means if there is reason to suspect rotor problems.

REASSEMBLING

Reassembly of the unit should be performed in a clean area. Where manufacture reassembly specifications are not available, refer to the ICRA manual for guidance. When using unfinished bearings, the finish bore should be accomplished in an align boring machine to assure proper shaft alignment. All bolts should be torqued to industry specifications. Compression type terminals should be replaced with new components to assure proper sealing. Upon completion of assembly the unit should be pressure tested and charged with oil.

REASSEMBLING

Reassembly of the unit should be performed in a clean area. Where manufacture reassembly specifications are not available, refer to the ICRA manual for guidance. When using unfinished bearings, the finish bore should be accomplished in an align boring machine to assure proper shaft alignment. All bolts should be torqued to industry specifications. Compression type terminals should be replaced with new components to assure proper sealing. Upon completion of assembly the unit should be pressure tested and charged with oil.

TESTING

All compressors should be test run under proper monitored voltage and amperes and the following should be checked:

Oil Pressure

Proper Operation of Suction and Discharge Valves

Unloaders For Correct Internal Operation

FINISHING

Unit should be sealed with a positive holding charge of dry nitrogen and painted.

FINISHING

Unit should be sealed with a positive holding charge of dry nitrogen and painted.

© 2025 International Compressor Remanufacturers Association - All Rights Reserved.

Created By

Captevrix